The Case of Central Beams in Hollow Profiles: Influence of Die Design on Extrudate Temperature

Abstract

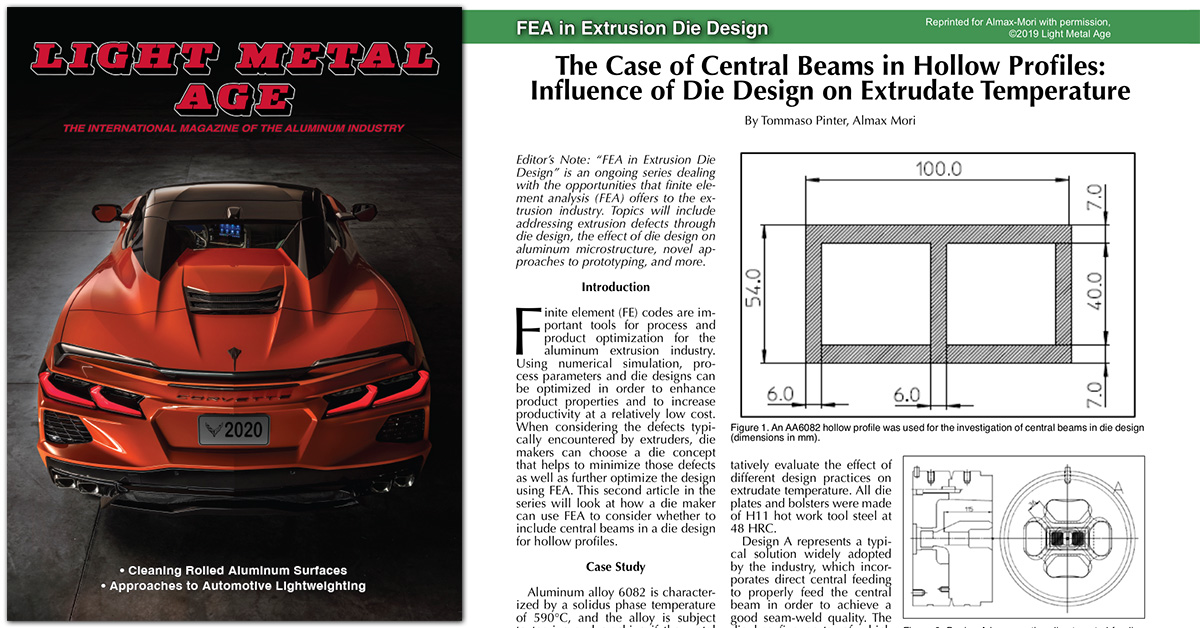

Finite element (FE) codes are important tools for process and product optimization for the aluminum extrusion industry. Using numerical simulation, process parameters and die designs can be optimized in order to enhance product properties and to increase productivity at a relatively low cost. When considering the defects typically encountered by extruders, die makers can choose a die concept that helps to minimize those defects as well as further optimize the design using FEA. This second article in the series will look at how a die maker can use FEA to consider whether to include central beams in a die design for hollow profiles.